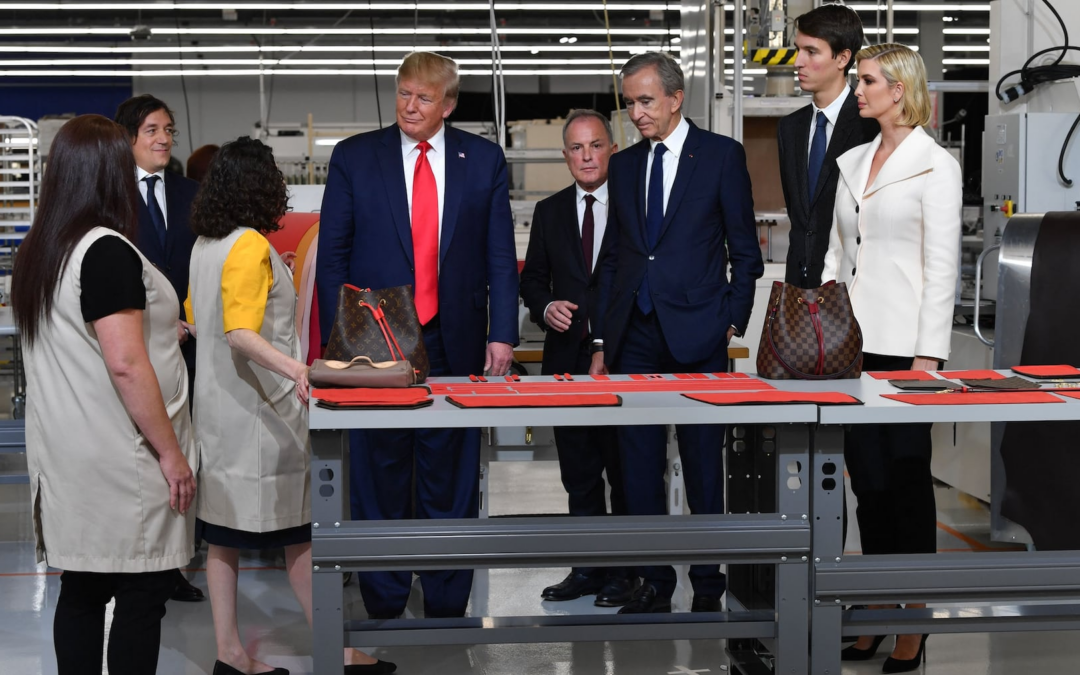

Six years in the past, LVMH’s billionaire chief government officer Bernard Arnault and President Donald Trump lower the blue ribbon on a manufacturing facility in rural Texas that will make designer purses for Louis Vuitton, one of many world’s best-known luxurious manufacturers.

However for the reason that high-profile opening, the manufacturing facility has confronted a number of issues limiting manufacturing, 11 former Louis Vuitton staff advised Reuters. The positioning has constantly ranked among the many worst-performing for Louis Vuitton globally, “considerably” underperforming different services, based on three former Louis Vuitton employees and a senior trade supply, who cited inside rankings shared with employees.

The plant’s issues — which haven’t beforehand been reported – spotlight the challenges for LVMH because it makes an attempt to construct its manufacturing footprint within the US to keep away from Trump’s threatened tariffs on European-made items.

“The ramp-up was tougher than we thought it will be, that’s true,” Ludovic Pauchard, Louis Vuitton’s industrial director, mentioned in an interview on Friday in response to detailed questions on Reuters findings.

The Texas web site, located on a 250-acre ranch, has struggled resulting from an absence of expert leather-based employees capable of produce on the model’s high quality requirements, the three former employees advised Reuters. “It took them years to start out making the easy pockets of the Neverfull purse,” one supply aware of operations on the plant mentioned, referring to the traditional Louis Vuitton shoulder tote bag.

Errors made through the chopping, preparation and meeting course of led to the waste of as many as 40 % of the leather-based hides, mentioned one former worker with detailed data of the manufacturing facility’s efficiency. Business-wide, typical waste charges for leather-based items are usually 20 %, a senior trade supply mentioned.

A number of former staff who spoke to Reuters described a excessive stress atmosphere. To spice up manufacturing numbers, supervisors routinely turned a blind eye towards strategies to hide defects, and in some instances inspired them, 4 former staff advised Reuters.

Pauchard acknowledged there had been such instances prior to now, however mentioned the problem had been resolved. “This dates again to 2018 and one specific supervisor who isn’t a part of the corporate anymore,” he mentioned.

Poorly-crafted purses deemed unfit on the market are shredded on-site and carted away in vehicles for incineration, two of the sources with data of the agency’s provide chain mentioned.

A former manufacturing supervisor who usually travelled to the positioning, mentioned Louis Vuitton principally used the Texas plant for much less refined purse fashions, producing its costliest merchandise elsewhere.

Pauchard, Louis Vuitton’s industrial director, mentioned the corporate was being “affected person” with “a younger manufacturing facility.”

“Any bag that goes out of it should be a Louis Vuitton bag, we ensure it meets precisely the identical high quality,” he mentioned. “I’m not conscious of any sorts of points suggesting the standard coming from Texas is any completely different from that coming from Europe.”

Made in USA

Perched behind a hill, the purse maker’s two manufacturing services had been constructed on grounds close to grazing cattle and a gasoline properly. Louis Vuitton named the positioning Rochambeau in tribute to a French normal who fought within the Revolutionary Struggle.

Staff on the web site make elements and full fashions of Louis Vuitton purses like Felice pochettes and Metis luggage – with “Made in USA” tags inside. The gadgets promote for round $1,500 and $3,000 at high-end boutiques.

LVMH declined to remark when requested which purse fashions are totally or partially made in Texas however former employees interviewed by Reuters talked about the Carryall, Keepall, Metis, Felice and Neverfull purse traces among the many plant’s merchandise.

In its advertising materials, Louis Vuitton says its purses — sometimes made at French, Spanish or Italian leather-based ateliers by artisans often known as “petites mains” — are assembled utilizing a course of that it has perfected for the reason that mid nineteenth century. After chopping canvas and leather-based utilizing hand instruments and laser-cutting machines, they sew items collectively utilizing industrial stitching machines.

Staff on the Texas facility, which incorporates devoted flooring for chopping and for meeting in addition to a warehouse, had been initially paid $13 per hour. As of 2024, base pay for a leather-based employee place on the plant was $17 per hour, based on two individuals who not too long ago utilized for positions. The minimal wage in Texas is $7.25 an hour.

A former leather-based employee who arrived as a migrant within the US some years earlier than, mentioned she felt proud when she was employed by the celebrated French model, however mentioned some employees struggled to satisfy the model’s high quality requirements and manufacturing targets.

“We had been beneath a whole lot of stress to make the each day targets,” mentioned the previous employee, who left the manufacturing facility on the finish of 2019.

One other one who labored on the facility till 2023 mentioned she lower corners, like utilizing a sizzling pin to “soften” canvas and leather-based to hide imperfections in a very tough piece referred to as the Vendome Opera Bag.

One other former leather-based employee mentioned they’d seen individuals soften materials to cover holes or different imperfections in stitching.

Damien Verbrigghe, Louis Vuitton’s worldwide manufacturing director, conceded some on the Texas plant had chosen to vary jobs or depart due to its stringent high quality necessities.

“There are artisans that we rent, who we prepare and who, after a number of weeks, or months, understand in gentle of the expectations, the extent of element that’s required, they might quite work in different fields like logistics,” he mentioned. “Some individuals selected to depart us, as a result of it’s true that it’s a job that requires a whole lot of savoir faire.”

Three former employees on the plant mentioned they acquired between two and 5 weeks of coaching. A present Louis Vuitton worker in France mentioned receiving just some weeks of coaching wasn’t uncommon as most studying occurs on the manufacturing line supervised by extra skilled craftspeople.

“Data of stitching on leather-based/canvas is a plus, however not required. We provide complete coaching,” the corporate mentioned in a job posting for artisan positions in Alvarado revealed on its web site in January.

Verbrigghe mentioned coaching in Texas is “precisely the identical program that we’ve in all our workshops,” that’s, six weeks on the coaching line, the place new artisans do nothing however study fundamental operations and abilities earlier than occurring to coach on the meeting line. There, he mentioned, they’re “accompanied and repeatedly mentored by trainers.”

Tax Breaks

LVMH received a number of tax breaks and incentives from Johnson County, together with a 10-year, 75 % property tax lower, promising the corporate an estimated $29 million in financial savings. ”We look ahead to serving this distinctive firm,” wrote the county’s prime government, Roger Harmon, in 2017 correspondence seen by Reuters.

In its 2017 software letter for the tax abatement, obtained by Reuters by means of data request, LVMH mentioned it was aiming to rent 500 individuals throughout the first 5 years of the plan. On the ribbon-cutting ceremony in 2019, Arnault mentioned, “We are going to create roughly 1,000 high-skilled jobs right here at Rochambeau over the following 5 years.”

Three former staffers, nonetheless, mentioned headcount stood at just below 300 employees in February 2025, a determine Verbrigghe confirmed.

The White Home didn’t reply to a Reuters request for remark.

Pauchard mentioned preliminary recruitment difficulties had been largely because of the Covid-19 pandemic and the lockdown that adopted, including {that a} decline in native demand additionally performed a task.

Regardless of the issues, LVMH is planning to maneuver much more jobs to Texas. LVMH mentioned in its 2017 submitting that its first Texas manufacturing facility would price round $30 million. A second submitting from 2022 to native authorities put the price of its second workshop, accomplished final yr, at $23.5 million.

At a city corridor final fall, employees at considered one of two California manufacturing websites had been advised that it will shut 2028 they usually may transfer to Texas or give up, based on a former worker who was current.

Pauchard confirmed the city corridor and mentioned Louis Vuitton supposed to streamline its California operations and switch extra expert artisans to Texas – with to date restricted success. Its executives, he mentioned, “underestimated the truth that Texas is way away from California.”

By Tassilo Hummel and Waylon Cunningham; Editors: Vanessa O’Connell and Michael Learmonth

Be taught extra:

Trump’s Tariffs: Assessing the Impression, One Week Later

Because the shock wears off, vogue companies are beginning to attract up plans to navigate a market that’s nonetheless quickly altering beneath their ft.

Disclosure: LVMH is a part of a gaggle of buyers who, collectively, maintain a minority curiosity in The Enterprise of Trend. All buyers have signed shareholders’ documentation guaranteeing BoF’s full editorial independence.